Introduction: The importance of filtration in the water industry

In today’s world, the scarcity of clean water has become a global challenge, and the use of efficient water purification systems has become more important than ever. Pressure sand filters are one of the most widely used and economical physical filtration methods in various industries. The system utilizes the simplest physics principles to efficiently remove suspended particles and turbidity from water.

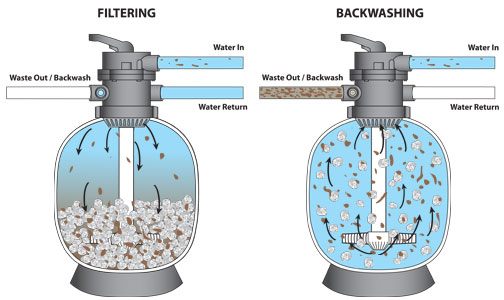

How the pressure sand filter works

The working principle of pressure sand filters is based on the physical mechanism of surface and deep filtration. In this system:

-

Contaminated water enters the filter tank under pressure (usually between 2 and 10 bar).

-

Water flows through a silica bed with a specific particle size.

-

Suspended particles are trapped as they pass through the sand layer.

-

The purified water flows out of the filter outlet.

Focus: The pressure in the system speeds up filtration and improves filtration efficiency.

The main components of the pressure sand filter

The main components of the pressure sand filter

A standard pressure sand filtration system consists of:

1. Filter tank

• Material: carbon steel, stainless steel or fiberglass

• Shape: Vertical or horizontal cylinder

• Equipped with an inspection port (manhole).

2. Filter bed

• Top layer: anthracite with a particle size of 1-2 mm

• Middle layer: silica sand with a particle size of 0.5-1 mm

• Bottom layer: coarse sand with a particle size of 3-5 mm

3. Water supply system

• Plastic or steel nozzles

• Evenly distributed piping system

4. Backwash system

• Backwash pump

• Related pipes and valves

• Cleaning wastewater discharge

Advantages of using a pressurized sand filter

Advantages of using a pressurized sand filter

-

Efficient: Capable of removing particles up to 20 microns

-

Low Operating Costs: Low energy consumption and limited chemical requirements

-

Flexibility: Capable of working at different flow rates from 5 to 500 cubic meters per hour

-

Long service life: With proper care, it can last up to more than 10 years

-

Easy to operate: no professional operator required

Industrial applications of pressure sand filters

• Water treatment in swimming pools and water parks

• Pretreatment of reverse osmosis (RO) systems

• Food and beverage industry

• Cooling tower backwater treatment

• Oil, gas, and petrochemical industries

• Water circulation systems in the textile industry

Factors affecting the choice of pressure sand filter

-

Influent water quality: turbidity and TSS

-

Required flow rate: The volume of purified water per unit time

-

Available space: Choose between vertical or horizontal models

-

Pressure Limit: The maximum pressure the system can withstand.

-

Tank material: steel, stainless steel or fiberglass

Optimal maintenance and operation

To achieve optimal performance of pressure sand filters, it is essential to pay attention to the following:

-

Regular backwashing: When the differential pressure increases to 0.5-1 bar

-

Regular control of silicon beds: replacement every 3-5 years

-

Annual Fuel Tank Inspection: Prevents corrosion and mechanical damage

-

Output water quality control: turbidity and TSS measurements

Conclusion

As one of the most economical and effective physical filtration methods, pressure sand filtration occupies a special place in various industries. The simple design, low operating costs, and acceptable efficiency make this system ideal for many industrial applications. With the right capacity selection and optimal design, you can enjoy the best performance of this system for many years.